News About Us

Chassis Parts Maintenance: Ensuring Longevity and Performance with JP Group

The chassis of a vehicle is its foundation—supporting the engine, suspension, wheels, and other critical components. As such, chassis parts play an essential role in the performance, safety, and comfort of a vehicle. However, like all automotive components, they require proper maintenance to ensure they remain in optimal condition. Without regular maintenance, chassis parts can wear out, leading to compromised vehicle handling, increased repair costs, and, in some cases, safety risks. In this article, we will discuss the importance of chassis parts maintenance, focusing on JP Group’s high-quality automotive parts, and provide tips on how to properly care for these essential components.

What are Chassis Parts?

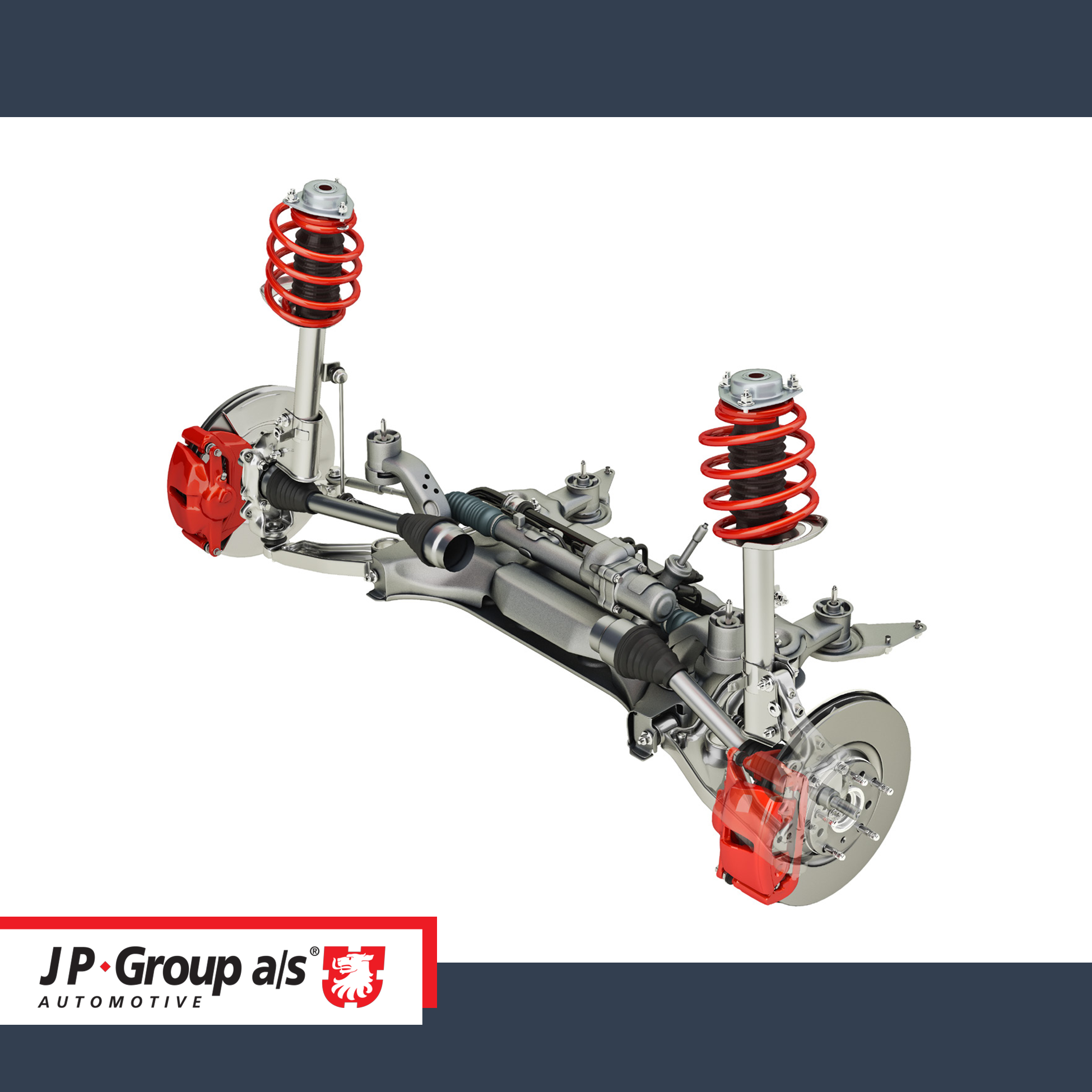

Before diving into maintenance, it's important to understand what chassis parts are and how they contribute to the overall functioning of a vehicle. Chassis parts are the components that make up the vehicle's frame, suspension system, and steering mechanisms. These include control arms, ball joints, tie rods, bushings, sway bars, shock absorbers, struts, and various other components that work together to ensure a smooth and safe driving experience.

These parts are crucial in providing stability, handling, and overall vehicle safety. They help the vehicle absorb shocks, maintain wheel alignment, and ensure precise steering control. Given their importance, it's essential to regularly maintain chassis parts to prevent wear and tear and prolong the vehicle's lifespan.

Why is Chassis Parts Maintenance Important?

Chassis parts are subjected to a lot of stress from constant use, road conditions, weather, and time. Over time, these parts can wear out, which can lead to a number of issues such as:

Reduced Handling and Stability: Worn-out chassis parts, like control arms or shock absorbers, can lead to poor vehicle handling, especially during cornering, braking, and acceleration.

Uneven Tire Wear: Misalignment due to damaged suspension or steering components can cause uneven tire wear, leading to costly replacements and reduced performance.

Safety Hazards: Faulty chassis parts can compromise the structural integrity of the vehicle, increasing the risk of accidents due to unstable handling or loss of control.

Increased Repair Costs: Ignoring chassis maintenance can lead to more serious issues, requiring costly repairs or even the replacement of the entire suspension system.

How to Maintain Your Chassis Parts: Tips and Best Practices

Maintaining your vehicle’s chassis parts is essential for ensuring that the vehicle remains safe, reliable, and high-performing. By following regular maintenance practices, you can extend the lifespan of your chassis components and keep your vehicle running smoothly. Below are some key tips for maintaining chassis parts:

- Regular Inspections

The first step in chassis parts maintenance is regular inspections. Inspecting chassis components for signs of wear and tear can help you identify potential issues before they turn into major problems. Here are a few things to look for:

Control Arms: Look for cracks, bending, or excessive wear in the bushings. Damaged control arms can affect alignment and handling.

Ball Joints: Check for looseness or play in the ball joints. If they are worn out, you may notice uneven tire wear or difficulty steering.

Tie Rods: Inspect tie rods for any damage or wear. Tie rods that are damaged can cause steering issues and uneven tire wear.

Suspension Components (Struts, Shocks, Springs): Look for leaks, signs of wear, or bent struts. Worn-out suspension components can lead to a rough ride, poor handling, and compromised vehicle stability.

A professional mechanic should be consulted for in-depth inspections, especially if you're unsure about the condition of any parts.

- Greasing and Lubrication

Chassis parts such as control arms, ball joints, and tie rods typically rely on grease for proper function. Over time, grease can dry up or wash away, leading to friction and premature wear. Ensure that parts with grease fittings are lubricated regularly to ensure smooth operation.

Use high-quality grease that is designed for automotive use and suitable for the specific parts.

Check the manufacturer’s recommendations for how often to grease certain parts and always follow the guidance for maintenance.

Regular lubrication helps to reduce friction, prevent corrosion, and extend the lifespan of chassis components.

- Replace Worn Bushings

Bushings are rubber or polyurethane components that help absorb vibrations and reduce friction between metal parts. Over time, bushings can wear out, crack, or become damaged. When this happens, it can lead to increased road noise, vibrations, and a harsher ride.

Check bushings for any visible damage or cracking.

Replace worn bushings promptly to prevent additional strain on suspension and steering components.

- Monitor Alignment and Suspension

Proper wheel alignment and suspension settings are crucial to ensure that the vehicle handles properly and that tire wear is even. Misalignment can lead to uneven tire wear, poor handling, and excessive strain on suspension components. To maintain your chassis system:

Get regular wheel alignments: If you notice that the vehicle pulls to one side or if the steering wheel is off-center, it could indicate an alignment issue.

Check suspension height: If your suspension system is sagging or uneven, it could indicate a problem with shock absorbers or struts.

JP Group offers a wide range of suspension parts, including shock absorbers and struts, that can help ensure your suspension system is in top condition for optimal driving performance.

- Replace Worn-Out Parts Promptly

Worn-out chassis parts should be replaced as soon as they show signs of failure. Ignoring damaged components will not only lead to worsening performance but could also put your safety at risk. Some common signs that a chassis part may need to be replaced include:

Excessive noise when driving over bumps or during turns.

Uneven tire wear that cannot be corrected by an alignment.

Vibrations or difficulty steering.

A rough ride due to worn suspension components.

JP Group offers a wide range of replacement chassis parts that meet or exceed OEM (Original Equipment Manufacturer) standards. Using high-quality parts for replacements ensures that your vehicle continues to perform at its best.

- Protect Against Rust and Corrosion

Chassis parts are exposed to the elements, including moisture, dirt, and salt, which can lead to rust and corrosion. To protect these vital components:

Wash your vehicle regularly to remove dirt, salt, and other debris that can cause corrosion.

Consider applying rust prevention treatments to the chassis and suspension parts, especially if you live in an area with harsh weather conditions.

The Role of JP Group in Chassis Parts Maintenance

JP Group is a leading manufacturer of high-quality chassis parts designed to meet or exceed OEM standards. The company offers a wide range of automotive components, including control arms, suspension parts and more. By choosing JP Group parts, you ensure that your chassis components are durable, reliable, and built to perform at their best for the long term.

JP Group's parts are engineered for easy installation and long-lasting performance, making them a trusted choice for vehicle maintenance and repairs. Their parts are available worldwide, ensuring that vehicle owners and mechanics have access to quality replacements whenever needed.

Conclusion

Chassis parts are integral to vehicle performance, safety, and comfort. Regular maintenance and timely replacement of worn components are essential for ensuring that your vehicle continues to run smoothly and safely. By following proper maintenance practices and choosing high-quality parts from brands like JP Group, you can extend the lifespan of your vehicle and enhance its overall performance. Regular inspections, lubrication, and replacement of damaged parts will help ensure that your chassis components remain in top condition, keeping you safe and comfortable on the road.

|

|

|

|